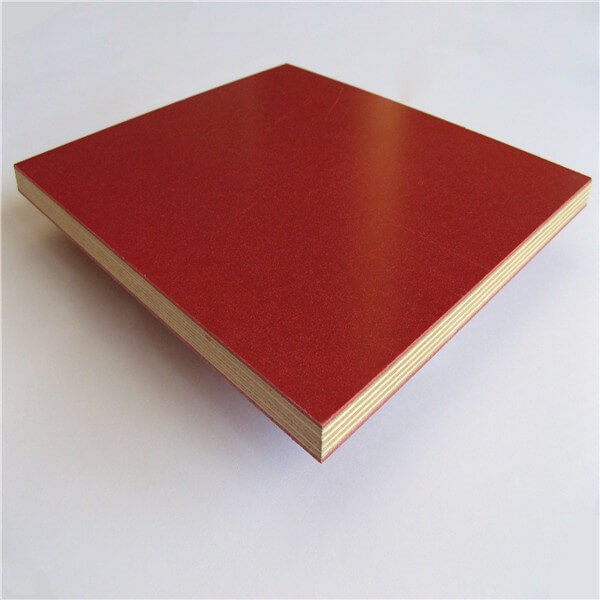

Film faced plywood

Plastic film faced plywood

film faced plywood is resistant to corrosion attack and water, easily combined with other materials and easy to clean and cut. Treating the film faced plywood's edges with waterproof paint makes it highly water-and wear-resistant. Due to its durability and easily handled surface it can be used in open environment in construction and building e.g. warehouses, railway wagons, floors and sidewalls of trucks etc. Coating the film faced plywood with high-quality import films ensures hardness and damage resistance. The surface of the film faced plywood is hygienic and resistant to strong detergents, which is important for farming constructions and storage of food products. It can be used in conditions of high temperature drop, influence of moisture, detergent cleaning and provides protection against termites.

We offer two types of film faced plywood.

The first being birch film faced plywood which is very resistant to water, easy to clean and cut and one of the world's best quality plywood's.

The second is poplar film faced plywood. This plywood type is also easy to clean and cut and is softer and lighter material than birch film faced plywood.

Features

1. Outstanding anti-slip performance

Surface treatment: usually embossing, sand coating (quartz sand or aluminum oxide particles), groove or coating process is used to

increase friction and prevent people or objects from slipping.

Applicable scenarios: Especially suitable for slippery environments such as wet, oily, sloped, such as docks, workshops, and car floors.

2. Wear and impact resistance

High-strength surface: Through sand coating or coating process, the surface wear resistance is significantly improved, and it can

withstand frequent trampling, heavy dragging or mechanical impact.

Extended service life: Compared with ordinary plywood, the anti-slip treatment layer can reduce surface wear and tear, suitable for

high-load use environments.