Fire Retardant Plywood Manufacturer

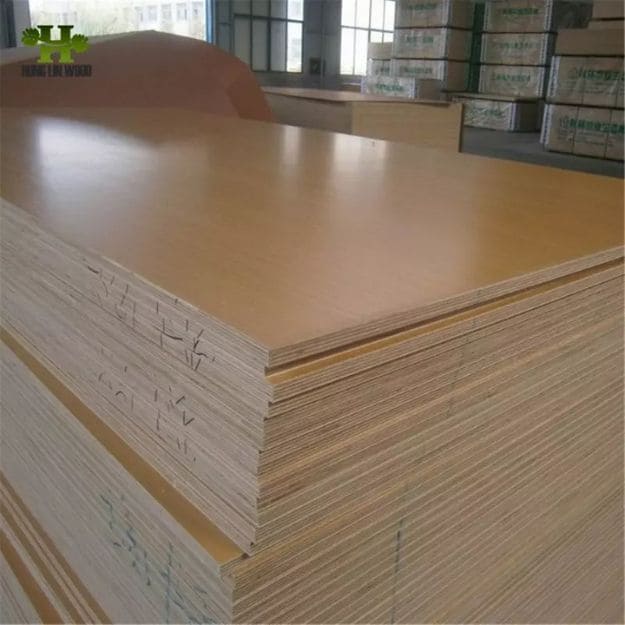

Fire retardant plywood is engineered wood treated with chemicals to resist ignition, slow flame spread, and reduce smoke. Ideal for construction, roofing, and interior walls in commercial buildings, it meets Class A standards like ASTM E84, enhancing safety in high-risk areas.

With over 18 years in plywood manufacturing since 2006, Cuzi excels in fire retardant solutions for construction, furniture, and industrial use. Our range includes film-faced plywood for durable builds, fancy plywood for designs, and melamine MDF for finishes, solving procurement challenges with certified quality.

Product Classification

Fire retardant plywood types include interior Type A (up to 95% humidity tolerance), Type B (up to 75% humidity), and exterior leach-resistant varieties. Classified by flame spread: Class A (0-25 index for maximum safety), Class B (26-75), and Class C (76-200) based on ignition resistance and smoke production.

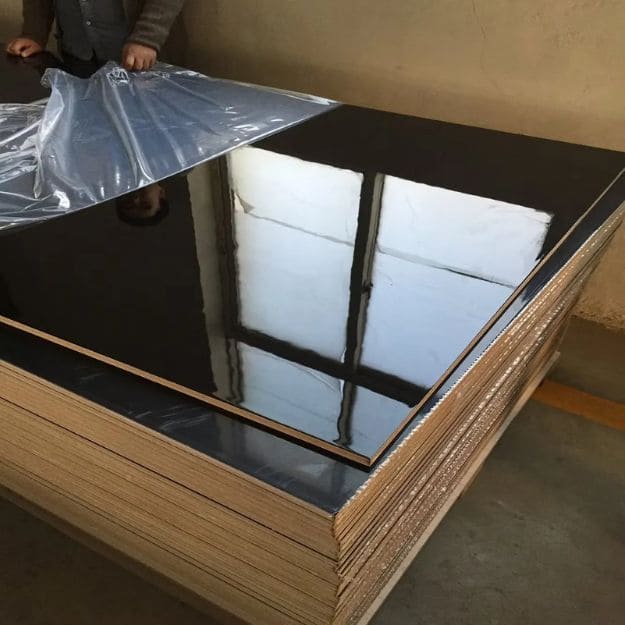

Our Best-Selling

Building on these varieties, at Cuzi, we manufacture all types of fire retardant plywood, from interior to exterior options, ensuring compliance with global standards. Our expertise allows us to customize solutions and provide expert consultation for your specific project needs in construction, furniture, or beyond.

- Interior Type A Fire Retardant Plywood Designed for indoor use with high humidity tolerance up to 95%, reducing flame spread and smoke in enclosed structural applications.

- Interior Type B Fire Retardant Plywood Suitable for lower humidity environments up to 75%, offering effective fire resistance for interior settings without direct moisture exposure.

- Exterior Fire Retardant Plywood Leach-resistant treatment for outdoor exposure to weather, maintaining fire-retardant properties in applications like roofing and siding.

- Class A Rated Fire Retardant Plywood Highest fire resistance with flame spread index of 0-25, ideal for high-risk commercial and residential areas requiring maximum safety.

- Class B Rated Fire Retardant Plywood Moderate fire resistance with flame spread index of 26-75, used in moderate-risk environments where stringent Class A standards are not mandated.

- Class C Rated Fire Retardant Plywood Basic fire resistance with flame spread index of 76-200, suitable for low-risk applications with minimal fire safety requirements.

Our Services for

At Cuzi, for Fire Retardant Plywood, we offer comprehensive services including custom manufacturing to your exact specifications, expert project consultation, material sourcing and certification verification, on-demand production in various sizes and grades, and reliable global shipping to ensure timely delivery for construction or furniture needs.

- Custom sizes

- Expert consultation

- Certified compliance

- Fast production

- Worldwide shipping

Possible Costs of

Procuring Fire Retardant Plywood is moderately expensive, with average costs of $50-120 per 4×8 sheet due to specialized chemical treatments enhancing fire resistance. Prices vary by thickness, brand, and region, but its safety benefits make it a worthwhile investment for construction.

Although Fire Retardant Plywood commands premium prices in global markets due to its advanced safety features, at Cuzi, our direct manufacturing in China enables us to provide it at rates 20-40% lower than local suppliers, without compromising quality.

- Product Cost:Base price per sheet, competitive due to in-house production and economies of scale (around $30-80 depending on specs).

- Packaging Expenses:Secure crating to prevent damage during transit, typically $5-10 per cubic meter for export standards.

- Ocean Freight:Shipping from China port to buyer’s destination, varying $500-2000 per container based on distance and fuel rates.

- Customs Duties:Import tariffs and VAT, often 5-15% of product value, depending on buyer’s country regulations.

- Insurance Premium:Coverage for transit risks, approximately 0.5-1% of total shipment value for peace of mind.

- Inspection Fees:Third-party quality and certification checks, $200-500 per order to ensure ISO/CE compliance.

- Payment Processing:Bank transfer or LC fees, around 1-2% of invoice, for secure international transactions.

- Local Delivery:Transport from port to site, estimated $100-300 per shipment within buyer’s region.

Frequently Asked Questions

What is fire retardant plywood?

Fire retardant plywood is a specially treated wood product designed to

resist ignition and slow the spread of flames, achieved through

pressure-impregnation with chemical retardants. It meets stringent safety

standards like ASTM E84 for Class A rating, reducing flame spread and smoke

development in case of fire. At Cuzi, we manufacture certified fire

retardant plywood that enhances building safety; contact us for customized

solutions tailored to your project needs.

Which plywood is fire-retardant?

Fire-retardant plywood includes brands like PyroGuard for interior use,

ExteriorFireX for outdoor applications, FlamePRO, and D-Blaze, all

pressure-treated with proprietary chemicals to achieve Class A fire ratings.

These are not inherently fireproof but significantly delay flame spread.

Cuzi offers high-quality fire-retardant plywood options compliant with ISO

and CE standards, helping you select the best for construction or furniture;

reach out for expert guidance.

How to identify fire-rated plywood?

Fire-rated plywood is identified by certification stamps or labels on the

panel, indicating compliance with standards like ASTM E84 (Class A flame

spread index 0-25), including manufacturer details, wood species, and

treatment type. It may have a pinkish tint from chemicals, but always check

for official markings. At Cuzi, our fire-retardant plywood comes with clear

certifications for easy verification; we can assist in ensuring your

selections meet regulatory requirements.

What company makes fire retardants for plywood?

Leading companies producing fire retardants for plywood include Hoover

Treated Wood Products (PyroGuard), Koppers Performance Chemicals (FlamePRO),

Viance (D-Blaze), and others like Albemarle Corporation and BASF for

chemical formulations. These provide treatments applied via pressure

impregnation. Cuzi partners with top suppliers to deliver treated plywood;

let us help source reliable fire-retardant products for your applications.

Is fire retardant plywood fireproof?

No, fire retardant plywood is not fireproof; it resists ignition and slows

flame spread but will eventually burn under prolonged exposure. The

treatment reduces flammability and smoke, meeting codes like Class A

ratings. Cuzi provides durable fire-retardant plywood that enhances safety

without false claims of being fireproof; consult us to integrate it

effectively into your designs.

Can fire retardant plywood be used outdoors?

Yes, specific types like ExteriorFireX are designed for outdoor use, with

treatments resistant to weather and humidity, while interior variants like

PyroGuard should stay dry. Always verify the label for intended application.

At Cuzi, we supply versatile fire-retardant plywood suitable for exterior

projects; our experts can recommend options that withstand environmental

conditions.

What are the applications of fire retardant plywood?

Fire retardant plywood is used in construction for walls, roofs, floors, and

partitions in high-risk areas like commercial buildings, schools, and

hospitals to comply with fire codes and enhance safety. It’s ideal for

structural and decorative purposes where flame resistance is crucial. Cuzi

offers customizable fire-retardant plywood for various applications; we can

support your project with tailored products and advice.

How is fire retardant plywood manufactured?

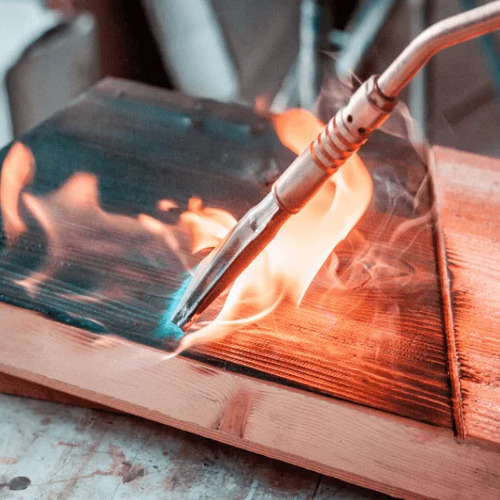

Fire retardant plywood is made by pressure-impregnating standard plywood

with chemical retardants in a vacuum chamber, followed by kiln drying to

lock in the treatment while maintaining structural integrity. This process

ensures even distribution for optimal fire resistance. As a leading

manufacturer, Cuzi employs state-of-the-art technology in our production; we

can provide detailed specs and samples for your evaluation.

What certifications should fire retardant plywood have?

Fire retardant plywood should carry certifications like ASTM E84 for flame

spread, UL listings, and compliance with International Building Code (IBC),

plus quality standards such as ISO 9001 and CE marking for global

acceptance. These verify safety and performance. Cuzi’s products are ISO and

CE certified; we can help you navigate certification requirements for your

specific market.

Is fire retardant plywood more expensive?

Yes, fire retardant plywood costs 20-50% more than standard plywood due to

specialized treatments and materials, with prices ranging $50-120 per 4×8

sheet depending on thickness and brand. The added safety justifies the

investment in code-compliant projects. At Cuzi, our efficient manufacturing

keeps prices competitive; contact us for quotes that offer superior value

without compromising quality.

What is the difference between fire retardant and regular plywood?

Regular plywood is untreated and highly flammable, while fire retardant

plywood is chemically impregnated to resist ignition, slow flame spread, and

reduce smoke, achieving ratings like Class A. This makes it safer for

building codes. Cuzi specializes in fire-retardant variants with enhanced

durability; we can guide you on transitioning from regular plywood for

improved safety.

Can fire retardant plywood be painted or stained?

Fire retardant plywood can be painted or stained, but use fire-retardant

compatible coatings to maintain its rating; avoid standard paints that may

compromise effectiveness. Test small areas for adhesion. Cuzi provides

pre-treated plywood ready for finishing; our team can recommend suitable

coatings to preserve fire resistance in your applications.

How long does fire retardant treatment last?

Fire retardant treatment in plywood is permanent when used indoors, as

chemicals are impregnated deeply and don’t leach out under normal

conditions. For exterior use, select weather-resistant types to ensure

longevity. Cuzi’s certified products offer long-term protection; we back

them with warranties and can advise on maintenance for sustained

performance.

Is fire retardant plywood environmentally friendly?

Modern fire retardant plywood uses eco-friendly, low-toxicity chemicals

compliant with GREENGUARD and other standards, minimizing environmental

impact while providing safety. Sustainable sourcing adds to its green

credentials. At Cuzi, our ISO-certified production emphasizes

sustainability; we can supply eco-conscious fire-retardant plywood options

for your green building projects.

The Manufacturing Process of

Fire retardant plywood manufacturing involves producing standard plywood from wood veneers, then enhancing fire resistance through pressure impregnation with specialized chemicals. This process ensures compliance with safety standards like ASTM E84, making it ideal for construction and furniture.

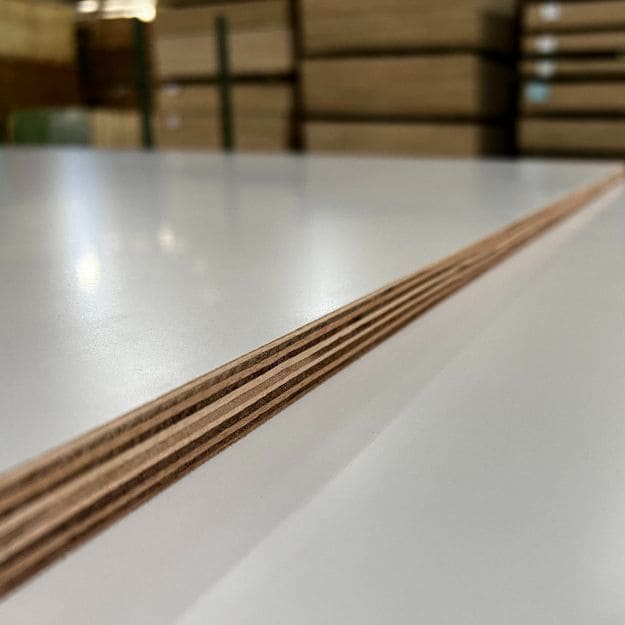

- Wood Selection and Veneer Preparation: Select high-quality logs, peel into thin veneers using rotary lathes.

- Veneer Drying: Dry veneers in kilns to reduce moisture content for better bonding.

- Gluing and Assembly: Apply adhesive to veneers, layer them cross-grained for strength.

- Hot Pressing: Press layers under heat and pressure to form solid plywood sheets.

- Sanding and Trimming: Sand surfaces smooth, trim to standard sizes.

- Fire-Retardant Treatment: Load plywood into pressure vessel, apply vacuum to remove air, inject FR chemicals under high pressure.

- Post-Treatment Drying: Kiln-dry treated plywood to stabilize and remove excess moisture.

- Quality Control and Certification: Test for fire resistance, certify to standards like ASTM E84.

State-of-the-Art Production Facilities

Eliminating Your Quality Concerns Before They Arise

When you select Cuzi for your plywood and MDF needs, you eliminate the frustrations of inconsistent quality—like delamination in humid environments, uneven surfaces that complicate your installations, or weak bonding that fails under stress—through our rigorous, multi-stage quality control system that spans from raw material intake to final shipment. We start by meticulously inspecting incoming timber and adhesives using ultrasonic scanners to detect hidden defects early, ensuring you never face surprises from subpar inputs that could warp or weaken your end products. During production, our automated monitoring systems track critical parameters like glue application uniformity and hot-press temperatures in real-time via IoT sensors, solving common pain points such as bubbling or incomplete adhesion by maintaining precise tolerances that exceed industry standards. For finished goods, we conduct comprehensive tests including boil-proof immersion for marine plywood to guarantee waterproof integrity, bend strength evaluations under simulated loads for film-faced variants to prevent formwork failures on your construction sites, and digital imaging for fancy plywood and melamine MDF to catch surface imperfections down to 0.1mm, so you receive flawless materials ready for seamless integration into your furniture or building projects. Backed by ISO9001 protocols and third-party audits, this end-to-end approach not only minimizes defects but empowers you with traceable batch reports, giving you the confidence to scale your operations without quality compromises.

- Raw Material VerificationEmploying X-ray densitometers and moisture meters to reject any logs or veneers exceeding 12% moisture content, directly addressing your concerns about warping or mold in storage and use.

- In-Process MonitoringIntegrated PLC systems that calibrate pressure up to 200 tons and heat cycles automatically, preventing delamination issues that plague lesser suppliers and ensuring your plywood withstands repeated formwork cycles.

- Final Product TestingUtilizing accelerated weathering chambers and tensile strength machines to simulate real-world stresses, resolving pain points like surface cracking or low durability by certifying each sheet meets or surpasses CE standards before it reaches you.

- Traceability and ReportingBlockchain-enabled tracking from source to delivery, providing you with detailed digital certificates that highlight compliance and performance metrics, so you can verify quality for your own audits or client assurances.

Application Scenarios

Fire retardant plywood enhances safety in construction by slowing flame spread and reducing smoke, ideal for walls, roofs, and floors in commercial buildings, schools, hospitals, and high-risk areas. Compliant with ASTM E84 and ISO/CE standards, it’s essential for code-required projects. Cuzi manufactures certified solutions for durable applications.

Commercial Buildings

In commercial structures like offices and retail spaces, fire retardant plywood is used for interior partitions, ceilings, and subfloors to meet stringent fire codes and prevent rapid fire spread. Its Class A rating ensures occupant safety during emergencies. At Cuzi, our 18+ years of expertise provide customized panels that integrate seamlessly into your builds for enhanced compliance and durability.

Educational and Healthcare Facilities

Schools and hospitals use it for walls, doors, and cabinetry to comply with safety regulations, minimizing risks in high-occupancy environments. Low smoke development is crucial for vulnerable populations. With Cuzi’s diverse, CE-certified products, we help ensure these facilities meet global standards while maintaining aesthetic appeal.

Residential Construction

For homes in wildfire-prone areas or multi-family dwellings, it’s applied in attics, garages, and exterior sheathing with weather-resistant treatments like ExteriorFireX. This delays ignition, giving time for evacuation. Cuzi’s innovative, ISO-certified plywood offers homeowners reliable protection; contact us to tailor solutions for your residential projects.

Hear From Our Clients

We believe in creating long-term partnerships based on trust and quality. See what our clients say about working with us.

Manufacturers Near Me

Top 8 Plywood Manufacturers in Vietnam 2025

July 16, 2025

Top 10 Plywood Manufacturers in Canada 2025

July 16, 2025

Top 10 Plywood Manufacturers in California 2025

July 16, 2025

Top 9 Plywood Manufacturers in USA 2025

July 16, 2025

Top 8 Plywood Manufacturers in Indonesia 2025

July 16, 2025

Top 11 Plywood Manufacturers in India 2025

July 16, 2025

Top 10 Plywood Manufacturers in China 2025

July 16, 2025

Let’s Get Started

Ready to elevate your construction or furniture projects with ? At Cuzi, we make it simple—fill out the form below with your details, and our experts will contact you quickly to discuss needs, offer custom quotes, and match you with ideal products for success. Seize our quality, customization, and partnership—submit now and let’s build together.

- Tailored Product RecommendationsReceive personalized suggestions based on your project requirements, ensuring you get the ideal film-faced or marine plywood without guesswork.

- Rapid Quote TurnaroundGet competitive pricing and detailed proposals within 24 hours, so you can keep your operations moving smoothly.

- Expert Consultation AccessConnect with our industry specialists for free advice on applications, certifications, and customizations that solve your unique challenges.

- Seamless Global DeliveryBenefit from our proven export network to China, Vietnam, and beyond, guaranteeing timely and cost-effective shipments for your wholesale needs.

Let's talk