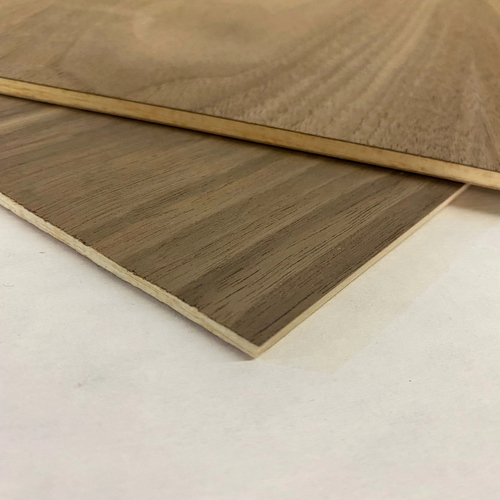

Walnut Plywood

Walnut plywood is an engineered wood panel featuring thin walnut veneer layers bonded for superior strength and stability. Known for its rich, dark grain and durability, it’s ideal for high-end furniture, cabinetry, wall paneling, and decorative projects where aesthetics and performance matter most.

At Cuzi, with over 18 years of expertise in plywood and MDF manufacturing since 2006, we deliver premium solutions for construction, furniture, and beyond. Our range includes film-faced plywood for durable builds, fancy plywood for elegant designs, melamine MDF for smooth finishes, and MDO/HDO options for demanding applications, ensuring reliable procurement and expert support.

Product Classification

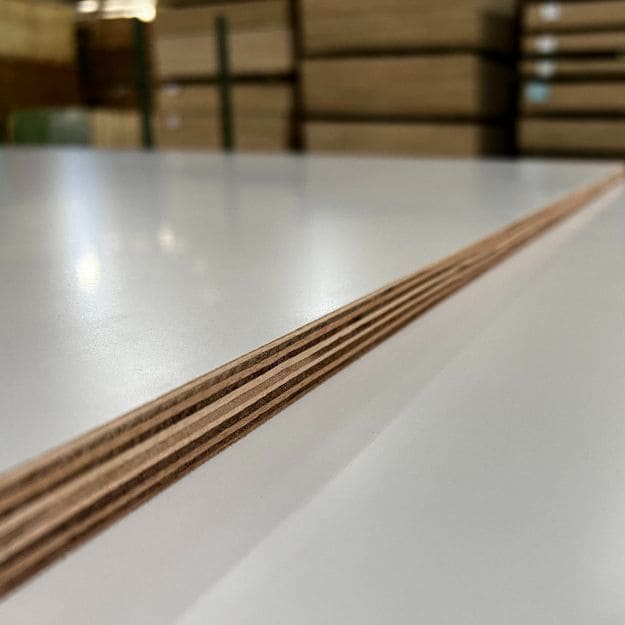

Walnut plywood types include flat cut (plain sliced) for a uniform grain pattern, quarter cut for straight lines and stability, rift cut for minimal figuring, prefinished for immediate use with protective coatings, and various cores like veneer for lightness or MDF for smoothness.

Our Best-Selling

At Cuzi, with over 18 years of expertise in plywood manufacturing, we produce all walnut plywood types, ensuring tailored solutions for your projects. We assist with customization, consultations, and solving procurement challenges to meet construction, furniture, or decorative needs.

- Flat Cut Walnut Plywood Features a broad, cathedral grain pattern ideal for furniture and cabinetry where aesthetic appeal is key.

- Quarter Cut Walnut Plywood Offers straight, striped grain with enhanced stability, suitable for high-end millwork and flooring applications.

- Rift Cut Walnut Plywood Provides a linear grain with minimal figuring, perfect for modern designs requiring uniformity and strength.

- Prefinished Walnut Plywood Comes with factory-applied finishes for protection and ease, used in ready-to-install interiors and fixtures.

- Veneer Core Walnut Plywood Lightweight with layered construction, great for general woodworking and cost-effective large panels.

- MDF Core Walnut Plywood Smooth and dense for precision cutting, ideal for painted or detailed furniture and cabinet faces.

Our Services for

We provide comprehensive services for Walnut Plywood, including custom manufacturing in various thicknesses, sizes, and finishes to fit your project needs. We offer expert consultations for material selection, rapid prototyping, bulk production with precision cutting and edging, global shipping, and after-sales support to ensure seamless integration in furniture, construction, or decorative applications.

- 18+ years expertise

- Customizable specifications

- Certified quality assurance

- Innovative processing tech

- Global trade solutions

Possible Costs of

Walnut plywood is expensive, with 4×8 sheets typically costing $120-250 depending on thickness (1/4″ to 3/4″), grade, and veneer quality, due to premium walnut hardwood, manufacturing processes, and high demand for durable, aesthetically rich panels in furniture and cabinetry.

Although walnut plywood is premium-priced on the market, at Cuzi our direct manufacturing in China and optimized supply chain enable us to offer competitive rates significantly below local market prices, delivering certified quality without added markups.

- Product CostBase price of Walnut Plywood panels, customized for size, thickness, and finish (e.g., $80-150 per sheet for bulk).

- Shipping FeesInternational freight from China, varying by volume and destination (e.g., $500-2000 per container).

- Customs DutiesImport taxes and tariffs based on country regulations (e.g., 5-10% of product value in the US).

- Packaging ExpensesSecure crating to protect during transit, typically 2-5% of order value.

- Product CostBase price of Walnut Plywood panels, customized for size, thickness, and finish (e.g., $80-150 per sheet for bulk).

- Shipping FeesInternational freight from China, varying by volume and destination (e.g., $500-2000 per container).

- Customs DutiesImport taxes and tariffs based on country regulations (e.g., 5-10% of product value in the US).

- Packaging ExpensesSecure crating to protect during transit, typically 2-5% of order value.

Frequently Asked Questions

What is walnut plywood?

Walnut plywood is a engineered wood panel with a thin walnut veneer on the

surface over a core of layered wood, offering the aesthetic of walnut with

enhanced stability and strength. It’s ideal for furniture and cabinetry. At

Cuzi, we can supply high-quality walnut plywood tailored to your

specifications for superior project outcomes.

Who are the top walnut plywood manufacturers?

Top manufacturers include North American Plywood, Weyerhaeuser,

Georgia-Pacific, Boise Cascade, and specialized suppliers like Anderson

Plywood and Columbia Forest Products. They offer various grades and types.

Cuzi, as a leading Chinese manufacturer, provides competitive, certified

walnut plywood with global standards compliance to meet your needs

efficiently.

Is walnut plywood expensive?

Yes, walnut plywood is premium-priced due to walnut’s limited availability,

slow growth, and high demand, with 4×8 sheets ranging $79-227 depending on

thickness and grade. It’s a worthwhile investment for durability. Cuzi

offers cost-effective options below market rates, helping you save while

ensuring quality for your projects.

What are the grades of walnut plywood?

Grades range from A (highest quality, no defects, for decorative surfaces)

to lower like B, C, D with more imperfections for structural use. A-grade is

ideal for visible areas. Cuzi provides customizable grades, certified ISO

and CE, to match your requirements and enhance project aesthetics and

performance.

Where can I buy walnut plywood?

Available from suppliers like Anderson Plywood, Rockler, Home Depot, and

online retailers such as Alibaba or Woodworkers Source, in various sizes and

thicknesses. Local lumber stores may stock it. Cuzi delivers directly from

China, offering bulk orders with shipping support for convenient,

cost-saving procurement.

What are the benefits of walnut plywood?

Benefits include excellent strength, dimensional stability, resistance to

shrinking/warping, and walnut’s rich aesthetic for furniture/cabinetry. It’s

more affordable than solid walnut. Cuzi ensures premium, certified walnut

plywood with innovative processing, helping you achieve durable, beautiful

results in construction or design projects.

What thickness options are available for walnut plywood?

Common thicknesses are 1/8″, 1/4″, 1/2″, 3/4″, up to 1″ for 4×8 sheets,

suitable for various applications from laser cutting to structural use. Cuzi

offers customizable thicknesses and sizes, backed by 18 years of expertise,

to fit your specific project needs precisely.

How does walnut plywood compare to solid walnut?

Walnut plywood is lighter, more stable, less prone to warping, and

cost-effective with veneer over core, while solid walnut offers natural

depth but higher cost and maintenance. Plywood suits large panels. Cuzi

provides high-value plywood alternatives, helping you balance quality and

budget effectively.

Is walnut plywood suitable for outdoor use?

Standard walnut plywood isn’t ideal outdoors due to moisture sensitivity;

use marine-grade or treated versions for exterior applications to prevent

delamination. Cuzi offers weather-resistant options like film-faced plywood,

ensuring durability for your outdoor construction projects with expert

guidance.

What projects is walnut plywood good for?

Ideal for cabinetry, furniture, wall paneling, decorative accents, and laser

cutting due to its beauty and strength. It’s versatile for interior designs.

Cuzi customizes walnut plywood for your projects, providing innovative

solutions to elevate aesthetics and functionality with reliable supply.

How to finish walnut plywood?

Sand smoothly, apply stain for color enhancement, then seal with varnish or

polyurethane for protection and sheen. Test on scraps first. Cuzi supplies

prefinished options or advises on finishing techniques, helping you achieve

professional results efficiently for your woodworking endeavors.

Is walnut plywood sustainable?

Depends on sourcing; look for FSC-certified products from responsible

manufacturers like Columbia Forest Products. Walnut grows slowly, so

sustainable practices matter. Cuzi prioritizes eco-friendly processing with

certifications, helping you source sustainable walnut plywood for

environmentally conscious projects.

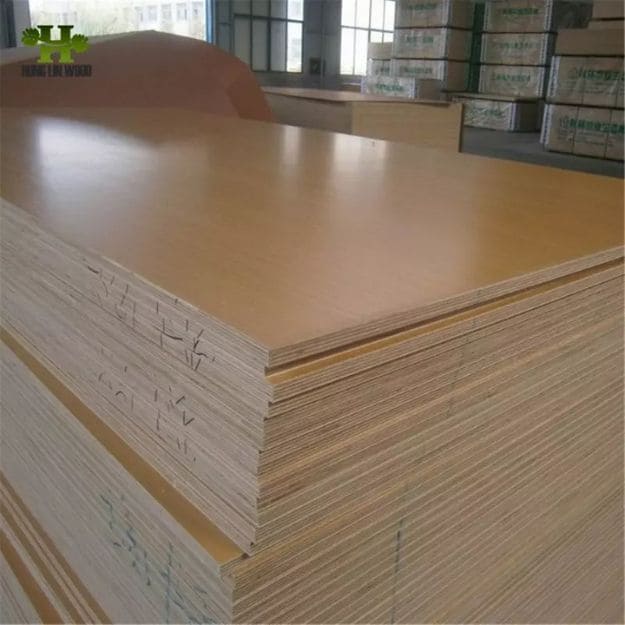

The Manufacturing Process of

Walnut plywood manufacturing starts with selecting walnut logs, debarking, and peeling into thin veneers. These are dried, graded, glued in cross-grained layers for strength, hot-pressed under high heat and pressure, then cooled, trimmed, and sanded to create durable panels for furniture and construction.

- Log Selection and Debarking Choose high-quality walnut logs and remove bark to prepare for peeling.

- Veneer Peeling Rotate logs against a blade to create thin walnut veneer sheets.

- Veneer Drying Dry veneers to reduce moisture for stability and bonding.

- Grading and Sorting Inspect and sort veneers by quality for face and core layers.

- Glue Application and Layering Apply adhesive and stack cross-grained veneers for strength.

- Hot Pressing Press layers under heat and pressure to bond into plywood.

- Cooling and Finishing Cool, trim, sand, and inspect final panels for quality.

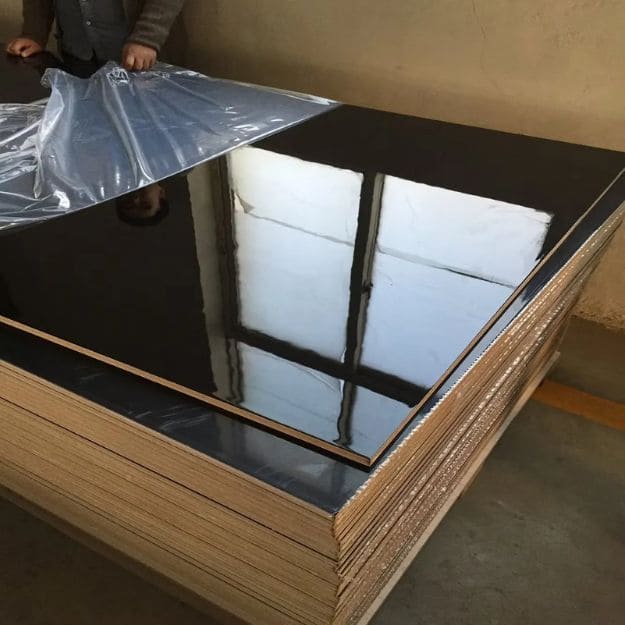

State-of-the-Art Production Facilities

Eliminating Your Quality Concerns Before They Arise

When you select Cuzi for your plywood and MDF needs, you eliminate the frustrations of inconsistent quality—like delamination in humid environments, uneven surfaces that complicate your installations, or weak bonding that fails under stress—through our rigorous, multi-stage quality control system that spans from raw material intake to final shipment. We start by meticulously inspecting incoming timber and adhesives using ultrasonic scanners to detect hidden defects early, ensuring you never face surprises from subpar inputs that could warp or weaken your end products. During production, our automated monitoring systems track critical parameters like glue application uniformity and hot-press temperatures in real-time via IoT sensors, solving common pain points such as bubbling or incomplete adhesion by maintaining precise tolerances that exceed industry standards. For finished goods, we conduct comprehensive tests including boil-proof immersion for marine plywood to guarantee waterproof integrity, bend strength evaluations under simulated loads for film-faced variants to prevent formwork failures on your construction sites, and digital imaging for fancy plywood and melamine MDF to catch surface imperfections down to 0.1mm, so you receive flawless materials ready for seamless integration into your furniture or building projects. Backed by ISO9001 protocols and third-party audits, this end-to-end approach not only minimizes defects but empowers you with traceable batch reports, giving you the confidence to scale your operations without quality compromises.

- Raw Material VerificationEmploying X-ray densitometers and moisture meters to reject any logs or veneers exceeding 12% moisture content, directly addressing your concerns about warping or mold in storage and use.

- In-Process MonitoringIntegrated PLC systems that calibrate pressure up to 200 tons and heat cycles automatically, preventing delamination issues that plague lesser suppliers and ensuring your plywood withstands repeated formwork cycles.

- Final Product TestingUtilizing accelerated weathering chambers and tensile strength machines to simulate real-world stresses, resolving pain points like surface cracking or low durability by certifying each sheet meets or surpasses CE standards before it reaches you.

- Traceability and ReportingBlockchain-enabled tracking from source to delivery, providing you with detailed digital certificates that highlight compliance and performance metrics, so you can verify quality for your own audits or client assurances.

Application Scenarios

Walnut plywood, prized for its rich grain and durability, is ideal for high-end furniture, cabinetry, interior paneling, architectural millwork, and decorative projects. As a leading manufacturer like Cuzi offers certified, customizable options, it ensures versatile use in construction and design, meeting global standards for premium wood solutions.

Interior Wall Paneling

Used in wall coverings and accent features, walnut plywood adds warmth and elegance to interiors. Its dimensional stability suits high-traffic areas, with Cuzi’s certified products ensuring compliance and easy installation for offices, hotels, and homes.

Cabinetry and Kitchen Design

Perfect for kitchen cabinets and storage units, walnut plywood provides a sophisticated finish resistant to warping. Cuzi’s innovative processing delivers smooth surfaces ideal for melamine overlays, supporting durable, customizable solutions for residential and commercial spaces.

Architectural Millwork

In doors, moldings, and trim, walnut plywood offers versatility for intricate designs. Cuzi’s high-performance materials withstand environmental changes, backed by ISO and CE certifications, making it a reliable choice for architects seeking premium, sustainable options.

Hear From Our Clients

We believe in creating long-term partnerships based on trust and quality. See what our clients say about working with us.

Manufacturers Near Me

Top 8 Plywood Manufacturers in Vietnam 2025

July 16, 2025

Top 10 Plywood Manufacturers in Canada 2025

July 16, 2025

Top 10 Plywood Manufacturers in California 2025

July 16, 2025

Top 9 Plywood Manufacturers in USA 2025

July 16, 2025

Top 8 Plywood Manufacturers in Indonesia 2025

July 16, 2025

Top 11 Plywood Manufacturers in India 2025

July 16, 2025

Top 10 Plywood Manufacturers in China 2025

July 16, 2025

Let’s Get Started

Ready to elevate your construction or furniture projects with ? At Cuzi, we make it simple—fill out the form below with your details, and our experts will contact you quickly to discuss needs, offer custom quotes, and match you with ideal products for success. Seize our quality, customization, and partnership—submit now and let’s build together.

- Tailored Product RecommendationsReceive personalized suggestions based on your project requirements, ensuring you get the ideal film-faced or marine plywood without guesswork.

- Rapid Quote TurnaroundGet competitive pricing and detailed proposals within 24 hours, so you can keep your operations moving smoothly.

- Expert Consultation AccessConnect with our industry specialists for free advice on applications, certifications, and customizations that solve your unique challenges.

- Seamless Global DeliveryBenefit from our proven export network to China, Vietnam, and beyond, guaranteeing timely and cost-effective shipments for your wholesale needs.

Let's talk